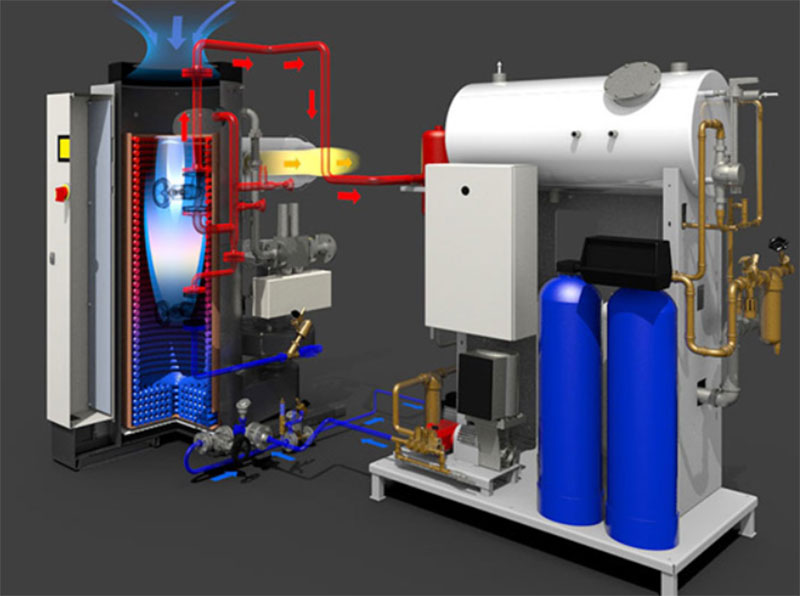

With 14,000 installations in over 130 countries, CERTUSS has built a reputation for safety and reliability worldwide. CERTUSS’ controlled circulation, once through watertube pressure vessel design, commonly referred to as a “steam generator”, is ASME rated up to 460 psig MAWP for every model CERTUSS builds. Thermal shock proof pressure vessel design means it can be fired “on-demand”, and can accept quick steam load changes without concern for damage. Ultra low operational water volume, a significant operational safety factor in generating high pressure steam, contributes to quick start times of 3-5 minutes from cold steel, and rapid responsiveness to varying steam loads. Further, the low water volume results in a very compact footprint for the respective steam capacity, especially compared to tubeless, and firetube boiler designs.

Unique air cooling of the outer jacket, which also serves to pre-heat combustion air, results in minimal radiant losses to ambient, and boosted combustion efficiency, resulting in 87% fuel-to-steam boiler efficiency, without the implementation of an optional flue gas economizer (by others). Optional Flue Gas Recirculation (FGR) contributes to reduced NOx.

CERTUSS boilers are all ASME stamped, and when purchased as a complete system, combining boiler, piping, wiring, and CVE accessory skid, provide the customer with UL certification not only for the boiler, but the entire system. Further, every CERTUSS system that leaves the factory has been fully pre-commissioned, testing and certifying the entire system before it arrives at the customer’s facility.

By using the water tube boiler principle, the CERTUSS technology for generating steam offers maximum safety, reliability and instant availability of high quality steam.