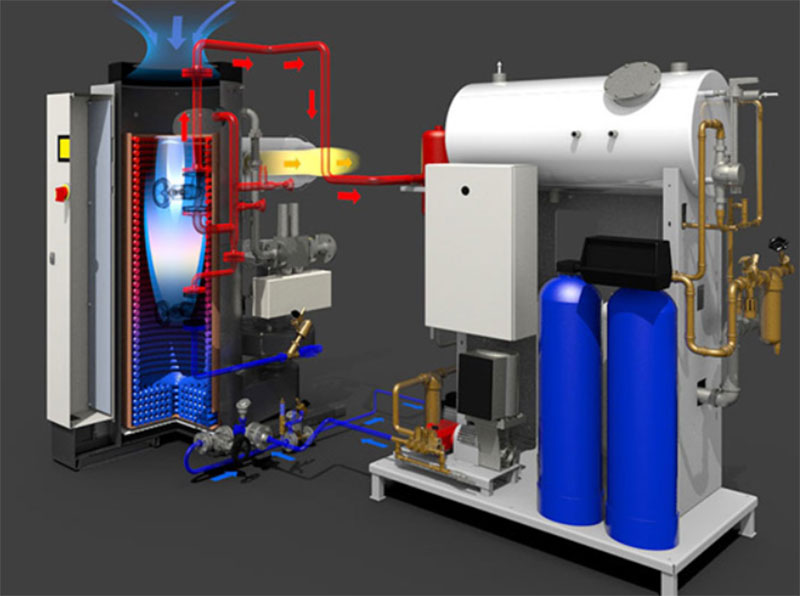

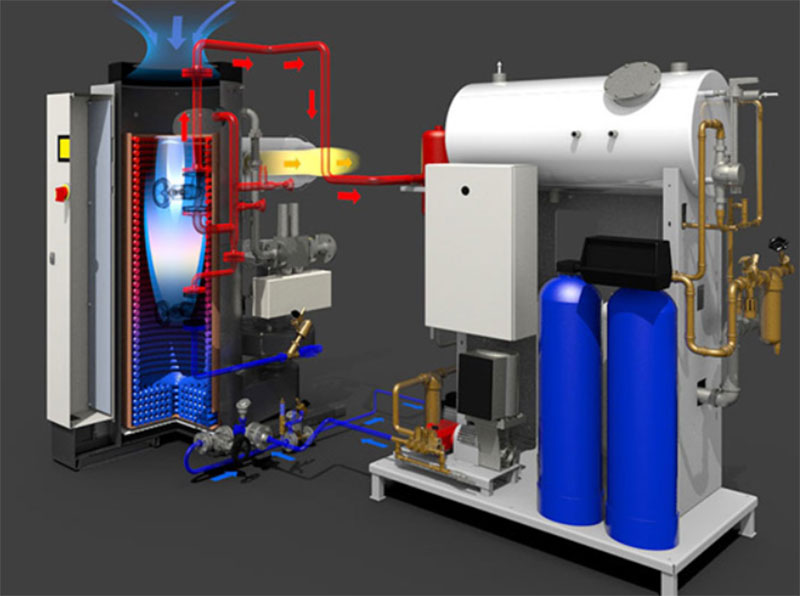

The Universal TC series offers our highest capacities, along with full burner modulation, and greater fuel flexibility. Various fuel types may be utilized, including LPG, natural gas, #2 oil or a dual fuel burner for natural gas and #2 oil. Universal TC model steam generators are equipped to efficiently serve constant, as well as fluctuating, high pressure steam demands. The touch screen control facilitates operation and gives a bundled overview of current pressures and configurations. All our Generators offer short heat up times and advanced options for remote access and operation.

| Model | Dimensions (inch) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Steam capacity lb/h | Height A | Width B | Depth C | Boiler Ø D | Flue gas pipe Ø E | Flue gas center F | Steam lines (NPS class 300) | Weight (~lb) | ||

| Universal | 500 | 1102 | 78 | 38 | 68 | 28 | 10 | 57 | 1 1/4″ | 2094 |

| 600 | 1323 | |||||||||

| 650 | 1433 | |||||||||

| 700 | 1543 | 90 | 46 | 76 | 34 | 12 | 69 | 1 1/2″ | 2425 | |

| 750 | 1653 | |||||||||

| 850 | 1874 | |||||||||

| 960 | 2116 | |||||||||

| 1000 | 2205 | 100 | 50 | 84 | 39 | 14 | 76 | 2″ | 3307 | |

| 1300 | 2866 | |||||||||

| 1500 | 3307 | 105 | 56 | 95 | 43 | 20 | 80 | 2 1/2“ | 5071 | |

| 1800 | 3968 | |||||||||

| 2000 | 4409 | |||||||||

By using the water tube boiler principle, the CERTUSS technology for generating steam offers maximum safety, reliability and instant availability of high quality steam.