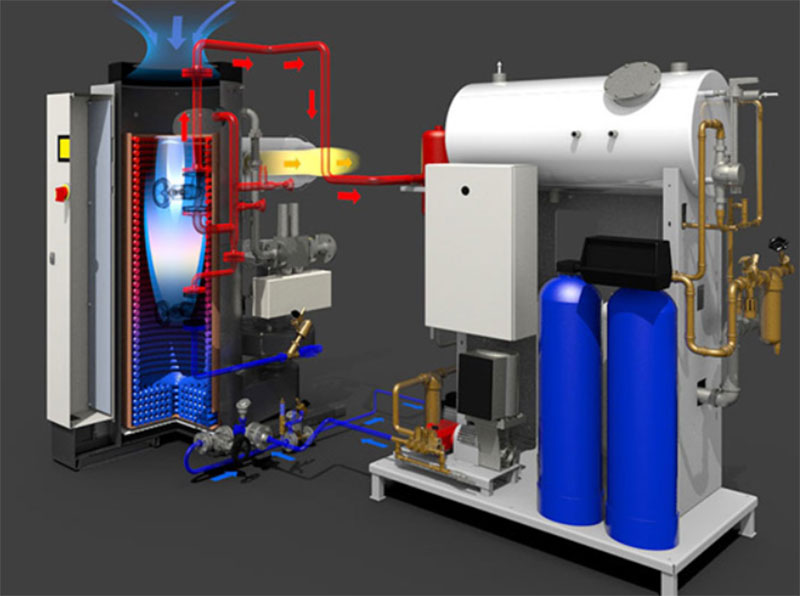

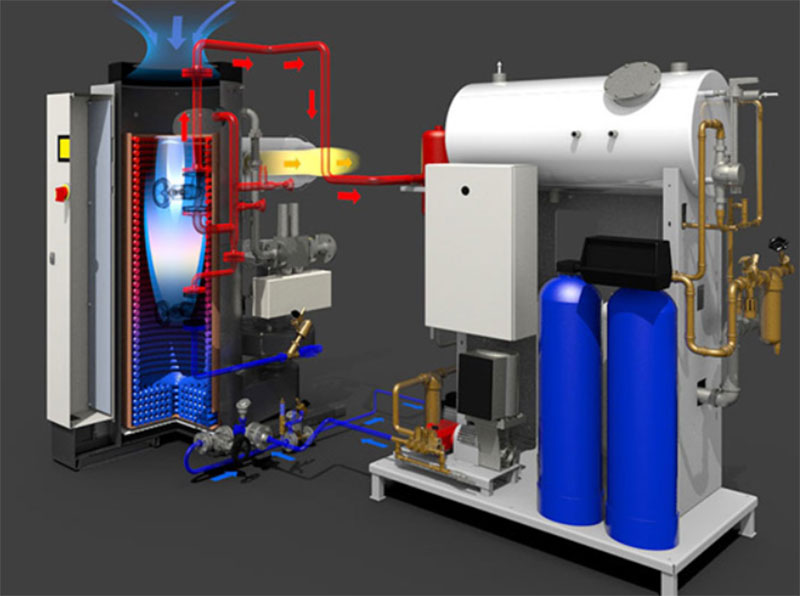

Just because you need a smaller capacity steam boiler for your process, doesn’t mean you should have to compromise on capabilities. So many smaller capacity steam boilers on the market today aren’t truly designed to meet the needs of sophisticated small industrial processes, leaving customers with choices that are ill-suited, or just plain undesirable. Instead, the CERTUSS Junior TC offers the same quick start up, on-demand performance, great touchscreen, automation, communication capabilities, and quality system components our customers appreciate in the larger Universal TC models.

| Model | Model Dimensions (inch) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Steam capacity lb/h | Height A | Width B | Depth C | Boiler Ø D | Flue gas pipe Ø E | Flue gas center F | Steam lines (NPS class 300) | Weight (~lb) | ||

| Junior | 80 | 176 | 60 | 29 | 51 | 20 | 7 | 41 | 1/2″ | 705 |

| 120 | 265 | |||||||||

| 150 | 331 | 63 | 29 | 58 | 22 | 8 | 44 | 3/4″ | 926 | |

| 200 | 441 | |||||||||

| 250 | 551 | 73 | 33 | 62 | 25 | 10 | 53 | 1″ | 1146 | |

| 300 | 661 | |||||||||

| 350 | 772 | |||||||||

| 400 | 882 | |||||||||

By using the water tube boiler principle, the CERTUSS technology for generating steam offers maximum safety, reliability and instant availability of high quality steam.